|

Know anyone who

can benefit from

this? Share! |

|

|

|

|

|

|

Custom bicycle geometry design

is the ultimate frontier in performance for the most advanced

and discerning cyclists. We offer the service of custom

designing a bicycle so that it fits yours specific body geometry,

builds on your strengths, minimizes your weaknesses and fits you

to perfection.

|

It's culmination of the perfect

relationship between human and machine.

Are you ready for the ultimate ride?

It's not as expensive as you think.

Compared to off-the-shelf, high-end bicycles, a Custom Geometry

may just be a bargain.

For some of the manufacturers we work

with, depending on material selection, the costs of a custom

geometry frame can start as little as $1,800. |

|

|

For those cyclists considering

a high-end bicycle, or desiring to reward themselves with the

ride of a lifetime, a custom bicycle is a very viable option

that will deliver the ultimate riding experience. Not even the

Pro riders get this kind of service!

Custom geometry design does not increase the purchase cost

significantly. On the contrary. Often, the end pricing of a

custom designed bicycle is comparable with the mid-line pricing

of a typical brand name - but you get the quality of the

high-end line.

Only the highest quality

materials and processes go into a custom bicycle, because this

is an artisan process: each bike is made one at a time with

the attention to details and workmanship pride that an assembly line

just cannot have.

No marketing gimmicks or flashy

ads to convince you the bike is more than it really is. Each

custom designed bicycle must earn its reputation one person at a

time. It must stand on its own to the scrutiny of only one

customer: you.

A custom designed bicycle will achieve the

best fit you have ever experienced; it will have the riding characteristics

you desire and it will reflect who you are as a cyclist.

A custom geometry designed bike

can achieve the ultimate bliss. |

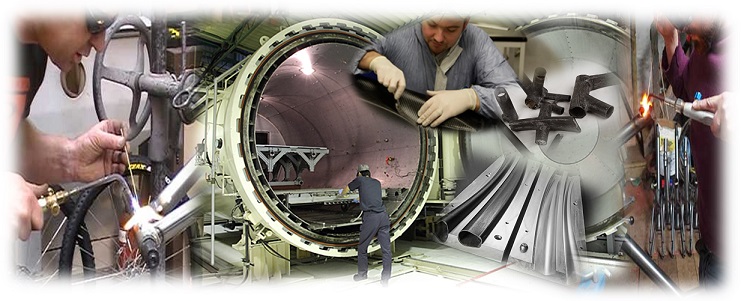

Craftsmanship in metals or carbon mould and bonding is

the hallmark of a custom bike. One piece at a time.

Looking for custom bike design pricing? Go

here. |

There are many reasons why a

cyclist may seek a custom design:

|

-

The best ride possible.

Spec your heart out. This is your bicycle!

-

The best performance

possible. You can have your bike designed to help you

win.

-

Specific preferences for

handling. You can tune the bike's handling characteristic to

match your riding style. Fast and responsive. Predictable

and stable. Whatever you prefer.

-

Comfort. Material

selection and geometry design can give the bicycle the feel

that you want.

-

One-of-a-kind bicycle that

fits you perfectly. Get your bike to feel a certain way

underneath you, move in-synch with you.

-

Specific application (ex: crit racing, climbing).

You can have a bike designed to do exactly the job you want

it to.

-

Atypical body geometry

(ex:

big and tall, small and short). Short legs and long torso?

Small stature? Or maybe you are as tall a Pro basketball player. The custom process designs a bike that fits your

specific body.

-

Injuries minimization (ex:

lower back range of motion limitations). If your are not as

flexible as you used to be or something prevents you from

finding comfort in an off-the-shelf bike, you can have a

geometry designed to fit you as you are - keeping the fun of

riding endless. It also allows you make the bike looks

exactly they way you want it. If you like a bike with very

few (to none) spacers under the

stem, but you must sit up, this is for you.

|

|

QUALIFICATIONS:

We draw from our

experience accumulated during the years working with

Colnago to design a bicycle that truly fits the way you

ride. We learned from the very best and now we can offer

that experience to you.

Combining the

accumulated knowledge of tradition and cutting-edge

computer technology, we put together a program that

rivals and exceeds the tools available to even most Pro

teams.

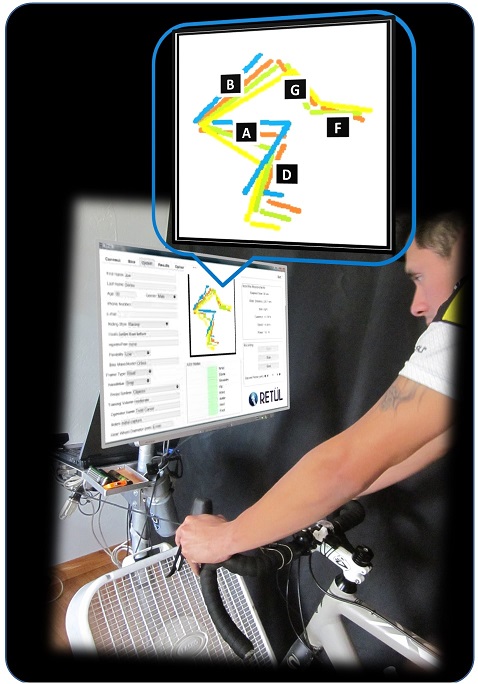

We combined the most

advanced technologies in bike fitting and bike sizing.

We leveraged Retül's 3D motion capture technology - the

world's Pro bench mark in bike fitting and sizing.

Then we developed

our own proprietary Dream Bike software and

bike sizing hardware to extract the most accurate information from

your dynamic interaction with the bicycle and design a

bike that moves with you.

No one goes to this

extent of passion, technology, tool

development, integration and design.

We agonized for years over every step of this process,

studying, researching, developing, inventing and

building every tool used in this process.

We can

literally build you a bike underneath you, starting from

the way you move with the bike and how that sets your

points of contact with the bicycle itself.

We turn the dynamic

bike fit data it

into a custom bicycle design that is as unique as you are, yet

steeped in proven performance - the design is always

proofed, no crazy geometries allowed.

It's a process of

perfection that yields the ultimate result in

personalizing your bicycle, the bike fit and the

performance. |

|

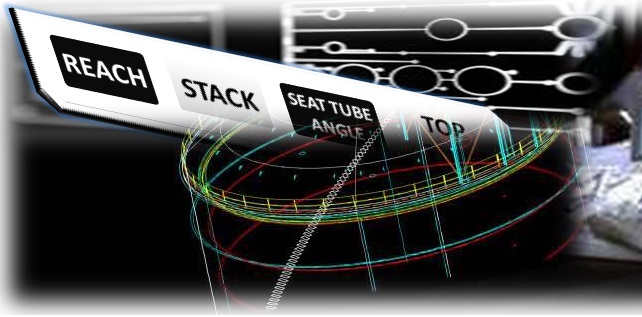

HOW DOES DYNAMIC MOTION CAPTURE CUSTOM BICYCLE

GEOMETRY DESIGN WORK?

We have taken the process of

bike design and brought it to the next level of customization to

match exactly your specific needs. Thanks to the revolution in

bike fitting and digital capture of bike measurements afforded

by the Retül 3D motion capture system, we were able to develop

hardware and software to complement and add to the technology,

so we can design a bicycle geometry that fits the

way you move.

The process starts with you

getting fitted on our custom-designed sizing bicycle using the

Retül 3D motion capture system to determine your best fit while

simulating different bicycle geometries and finding the best

size components (like the length of the cranks and the width of

the handlebar). This is a process very similar to our

bike sizing procedure,

with the biggest difference being that we don't start from a

published geometry, but with a blank slate.

|

The key to our process is the

Dynamic 3D Motion Capture data acquisition of your relationship

to your future bike. This data collection is done in real time,

while you pedal on the sizing bicycle using Retül 3D

motion capture technology.

Eight infrared laser sensors

broadcast the position of each of your body limbs 16 times per

second as you pedal under a simulated load. Retül builds a

database of these body postures - a staggering minimum of 256

positions! - and reports back all your critical measurements

in digital format.

Some of these measurements are

average positions you assume during pedaling. Some are maximum

and minimum positions you extend yourself into. They are

critical in the determination of what's possible for your body,

what must be protected and what can be optimized to get the best

out of your biomechanical potential.

This guides us to the design of

your bicycle, so it fits the way you move in real life.

Literally, we design the bicycle underneath you, using the

output of you dynamic motion capture data and the resulting

ideal points of contact with your bike.

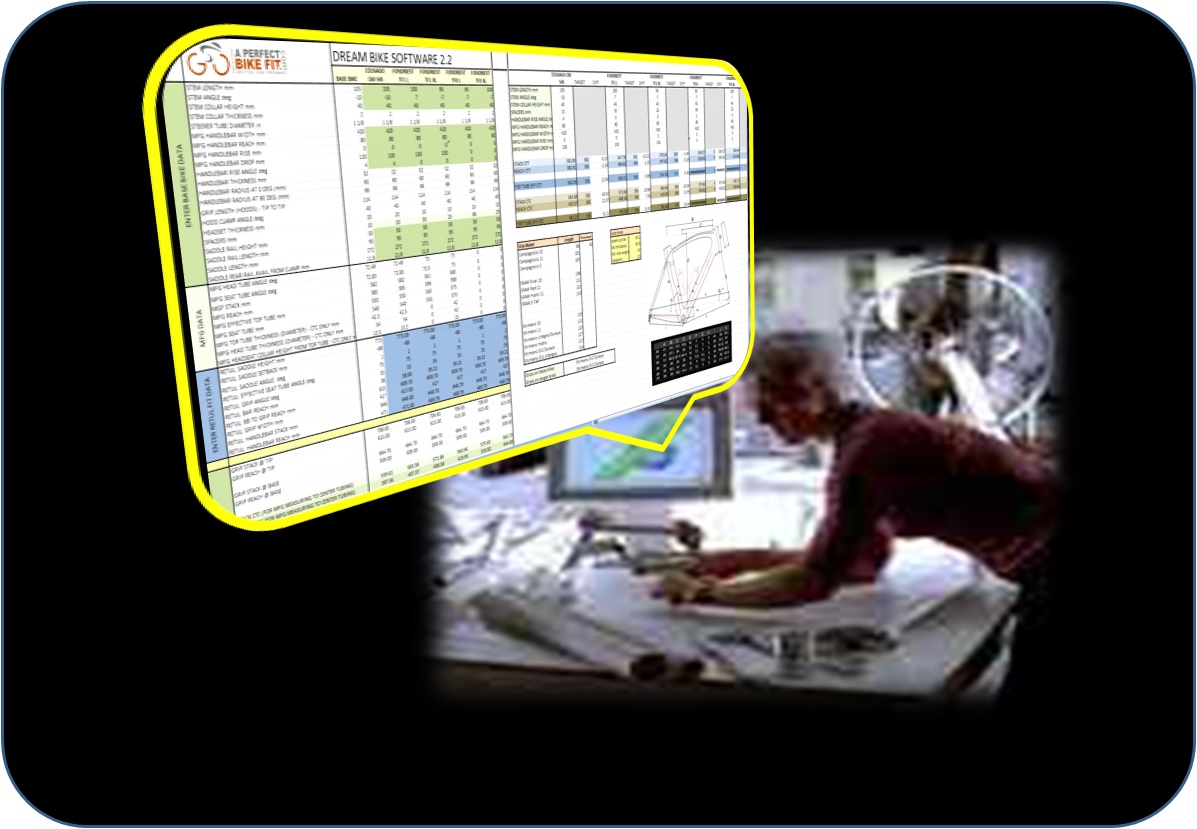

We have developed our own

proprietary software to extract the Retül data and turn it into

your bicycle design.

You can spec your favorite

components (like handlebar and seatpost) and preferences (like

length of the stem). Our software will help us design a bike

that fits you using the components you prefer - and we are able

to tell you if your choices are not optimal.

This is not only cutting edge,

but really a unique process that we apply to achieve unparallel

results.

You can find this custom design process with

only us.

HOW IS THIS DIFFERENT FROM TRADITIONAL BIKE

DESIGN?

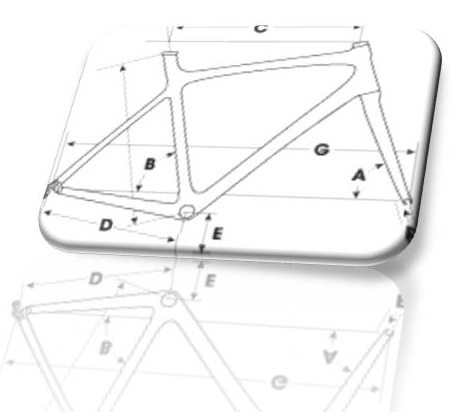

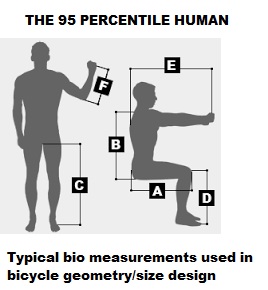

In static bike fit and geometry

design, biometric data is

accumulated with a single static gathering of your body critical

measurements: your standard anthropometrics (A, B, C, etc. as

seen in the diagram to the left). This is done simply with a tape

measure. In static bike fit and geometry

design, biometric data is

accumulated with a single static gathering of your body critical

measurements: your standard anthropometrics (A, B, C, etc. as

seen in the diagram to the left). This is done simply with a tape

measure.

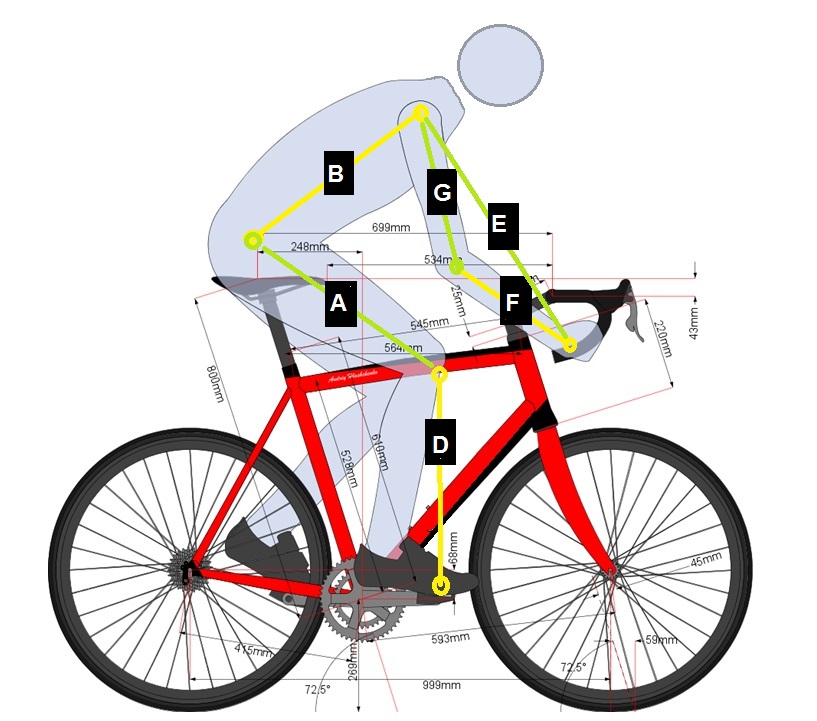

The bicycle designer applies

the measurements of your arms, legs and other limbs to a

fictitious human placed on a virtual bicycle at a predetermined

position (see diagram to the right). The bike and components are

sized based on that single static position and your

measurements.

This leads to the

oversimplification of the critical parameters that represent

your interaction with the bicycle.

It overlooks maximums and

minimums in your interface with the geometry, which can lead

to severe under-representation of your dynamic interaction with

the bicycle and to undesirable biomechanical behaviors.

Static bike fit based geometry

design averages out everything - even the size of components -

and relies on the final fit to actually get you aligned into the

bike. Just like a stock bicycle. So why bother with a

custom design when the results are so limited?

Sometimes, this process is done

on fancy, servo-motor controlled sizing bicycles (Guru and Trek

Precision Fit). Don't let that fool you. The sizing bike is only

part of the equation - an important part, but not as critical as

the data acquisition. The data for your bike fit and position

must be collected while in motion and with accuracy.

Video camera bike fitting systems are also not effective. They

suffer from tremendous accuracy problems because they are

stop motion capture systems, not real-time dynamic

data collection capable. They acquire one single position

data for your fit, bringing you back to the same-old,

outdated process.

Finally, the measurements data

acquisition on these sizing bikes is still done with a tape

measure. Can you imagine? Millimeters being rounded off here and

there and subject to human error!

That's why, in our opinion,

static-based bike fitting and bike design have become an

obsolete methodology. |

The Retül 3D motion captures every body movement while

you pedal and builds a database of interface at least

256 positions

with your bike.

Static bike fit based geometry design uses one single

position to determine your geometry. |

The difference in using our

approach to custom geometry design and the old process is

staggering. The improvements in results using a Dynamic Motion

Capture system as compared to the single static measurement

methodology are... dramatic. The computerized, laser-assisted

data acquisition of your custom bike measurements is accurate

within 1/10th of a millimeter. And the way our software works in

getting this extremely accurate data and turning into actionable design elements is

simply a brilliant development destined to change custom bicycle

design for ever.

And you can get it only in

our bike fitting studio.

WHAT IS

THE PROCESS?

The Custom Geometry Bicycle

Design is

a 3-step process:

|

1) Geometry

Interview and Bike Sizing

On the first day of the

custom geometry process you'll be working with us to

discuss your needs and expectation from your custom

bicycle.

-

Discuss the following:

- The

application of your bicycle (i.e. how you want

to use it)

- Choice of

materials

- Preferences

in handling

- Preferences

in performance

- Preferences

in design

- Group

components

A) Pre-fit analysis and history

The pre-fit analysis

allows us to learn about you and your body. In essence,

we learn what's possible and what's not, what maximizes

you and what needs to be protected.

-

Pre-fit analysis:

- Personal

history interview

- Flexibility

- Joint range

of motion

- Muscle

range of motion and activation

- Dynamic

interaction of key muscle groups

- Strength of

key muscle groups

- Gait

analysis

- Plantar

(foot) and

nerve analysis

B) Bike fit on sizing bicycle. Raw bicycle geometry

acquisition.

The sizing session

on the bike is where we make the most critical

decisions. Knowing what you want the bike to do, how you

plan to use and what your body can and shouldn't be

doing, we simulate geometries and change the size of the

components until we reach your ideal body position.

-

Bike fitting on sizing bicycle:

- Retül 3D

Dynamic motion capture on sizing bicycle

- Simulate

geometries compatible with stated application

- Size

components (cranks, handlebar, etc.)

- Digitize

bike measurements with Retül 3D Zin data capture

system

- E-mail data

(PDF format)

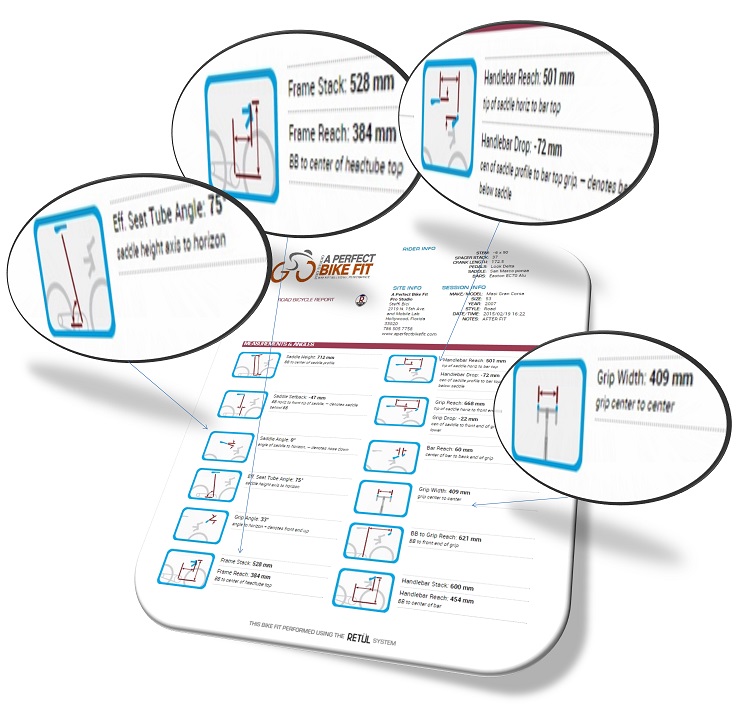

The process of bike

digitization is where we get the critical data to begin

the design process. Retül's unique 3D bike measurement

process is accurate within 1/10 of a millimeter. It uses

4 lasers on a CAD wand to extract the bike measurements

from the sizing bike. No measuring tape - or human

error. The process of bike

digitization is where we get the critical data to begin

the design process. Retül's unique 3D bike measurement

process is accurate within 1/10 of a millimeter. It uses

4 lasers on a CAD wand to extract the bike measurements

from the sizing bike. No measuring tape - or human

error.

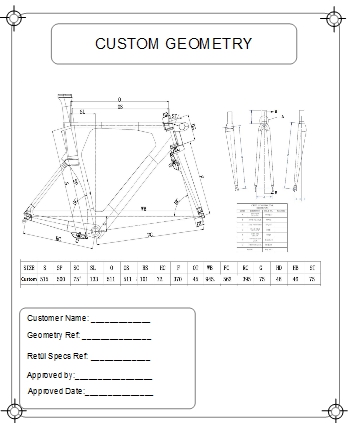

It creates a measuring map of your

body interaction with the sizing bike and gives us that

information. From here we can begin designing your bike. See here

a sample. |

Custom bikes can be made of your favorite material.

Carbon, Titanium or Steel. Aluminum too, if you so

desire. Your choice.

The sizing bicycle determines the ideal position and

geometry. It can simulate any geometry and any

component size to suit your special needs and

preferences. The bike fit position at this stage

determines your contact points and the raw

geometry before optimization for production.

The Retül 3D Zin digital capture of the sizing bike

after your optimized 3D motion capture bike fit yields

the raw geometry configuration from which we start the

optimization design. Click to see full image. |

| 2)

Custom Geometry Design

In the next several

days, the bicycle geometry is drawn from the Retül Zin

bicycle data acquired.

We'll do the

following:

- Import Retül 3D

Zin data into our proprietary Dream Bike software

- Design bicycle

with regards to your preferences and Retül data

- Discuss

geometry design outcome and limitations (if any)

- Submit to

chosen manufacturer

- Receive and

analyze manufacturer provisional production blue

print

- Discuss

manufacturer blue print and production compromises

(if any)

- Customer

submits approved blueprint to manufacturer.

Most manufacturers

will take 30-60 days for the production of the custom

bicycle. |

Retül data imported in our software allows us to design

a bicycle underneath your points of contact. Able to

simulate and compare several bike geometries, the Dream

Bike software is a powerful tool for your success.

|

| 3)

Bike Fitting on Custom Geometry Designed bicycle

This is the final day.

You will be fitted with Retül 3D motion capture to

fine-tune and finalize the position on your new custom

made bicycle. This is where we work to achieve the best

interaction between you and your custom designed

bicycle.

We'll do the

following:

- Do a series of

Retül 3D motion capture runs

- Make fine-tune

adjustments to your position to optimize you in the custom design

geometry

- Do pedal ID

analysis and power profile to optimize power output

(upgrade to PRO is optional)

- Finalize the

fit

- Digitize the

final fit on your custom geometry bicycle with Retül

3D Zin data capture system

- E-mail you a

set of reports (PDF file)

|

The final fit session on the actual custom designed

bicycle geometry is all about fine tuning and finding the perfect fit

on a bike designed for your body

|

PRICING:

We don't sell bicycles. We only

provide the bike sizing, design and fitting services. The

pricing for that service is

here.

We collaborate closely and

routinely with some manufacturers, but we are completely

agnostic and work with any manufacturer of your choice, big or

small.

The actual price of the custom

geometry designed bicycle is set by the manufacturer. We work

with many and some extend special pricing to our customers, but

not all do. Some charge a custom design fee - even though we do

most of the work together - because they have to translate the

measurements we give them into their own CAD system and they

need to proof the geometry - a very necessary step to ensure

success.

The procedure varies as much as

the options for a custom geometry.

A down deposit or a full down

payment is required by all manufacturers. Each custom geometry

manufacturer has a procedure for engaging customers. We leave to

you and them to work out those details. But we'll happily

advocate for you and the accuracy of the custom geometry

production.

Currently we work with the

following manufacturers:

|

Fondriest. |

|

Italian niche high-end

manufacturer that has been producing the lightest frames in the

record books - and yet, very resistant at 140N/mm. Steeped in

Italian tradition and bearing the racing pedigree of

Maurizio Fondriest, these bikes are the pinnacle of

custom design and manufacturing. |

|

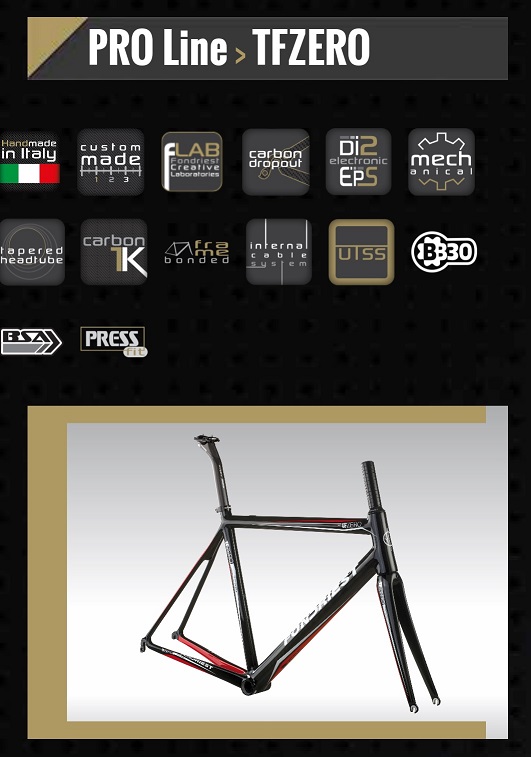

CARBON

|

TF0

- Lightest production bike

790 grams (size

54), 340 grams fork

(Compare to the industry high-end bike average of 900

grams frame and 450 grams fork).

Toray 40 Tons

Carbon, bonded, internal lugs, seamless design.

Carbon monolith

integrated dropouts on rear stays and fork.

OPTIMAL FOR:

Full custom design where the

ultimate light weight, lateral stiffness and comfort are

required.

SPECS AVAILABLE:

All geometry

parameters can be spec'ed, subject to manufacturer

production and safety proofing and approval.

Mechanical and

Electronic compatible

BB: choice: PF30,

BB30, ITA or ENG

100% made in Italy.

Hand bonded and hand-finished |

. . |

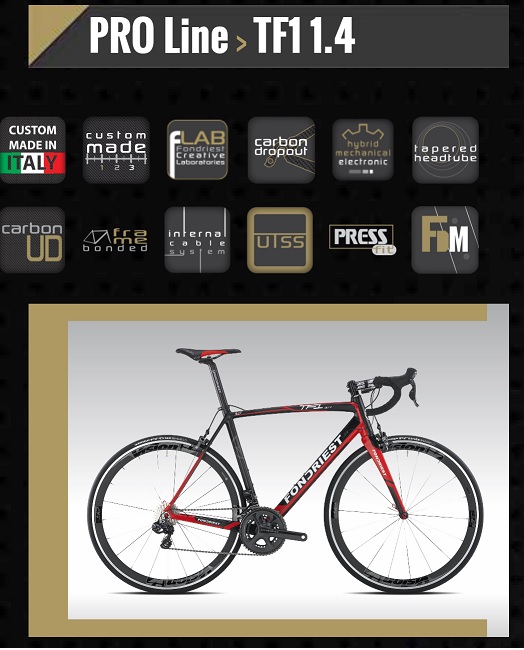

CARBON

|

TF1 - Super light aero

Born from the design of the TF0, the

TF1 is a more price-conscious bicycle - making it a best

bang for the buck.

795 grams

(size 54), 360 grams fork

(Compare to the industry high-end bike average of 900

grams frame and 450 grams fork).

Toray 40 Tons

Carbon, bonded, internal lugs, seamless design.

OPTIMAL FOR:

Full custom design where the

ultimate fit and comfort must meet a medium-line budget.

SPECS AVAILABLE:

All geometry

parameters can be spec'ed, subject to manufacturer

production and safety proofing and approval.

BB (PF30, BB30, ITA

or ENG)

Mechanical and

Electronic compatible.

Disc brakes option

BB: PF only

Custom made in

Italy. |

|

STEEL

|

SF2 / SFD - Steel

Born from tradition with a nostalgic

cycling golden-era look and all modern performance.

Lugged steel.

1490 grams

(size 54), 650 grams fork

Chrome-plated lugs,

bonded steel tubing, replica design.

OPTIMAL FOR:

Full custom design where the

ultimate comfort and look of steel meet the ultimate fit

on a very competitive budget.

SPECS AVAILABLE:

All geometry

parameters can be spec'ed, subject to manufacturer

production and safety proofing and approval.

Mechanical and

Electronic compatible.

Disc brakes option

Custom made in

Italy. |

| |

|

|

|

Samson |

|

South Florida born, near to our

location and our heart, Samson designs in Hialeah and produces

to specs in Taiwan light weight custom Titanium Mountain

Bikes and Cycle Cross Bikes.

The final product is

assembled in Florida. |

|

|

The Judge

Titanium hard tail available in 29

and 27.5. Light weight Cross Country race-inspired

bicycle with the comfort and stiffness of Ti.

OPTIMAL FOR:

Full custom design for X/C racer

or enthusiast, where the ultimate fit and comfort must

meet speed and a medium-line budget.

SPECS AVAILABLE:

All

geometry parameters can be spec'ed, subject to

manufacturer production and safety proofing and

approval. All

geometry parameters can be spec'ed, subject to

manufacturer production and safety proofing and

approval.

Custom laser etching

on tubing available.

Designed in Hialeah, made in

Taiwan. |

|

|

The Jury

Pivotless Titanium full suspension,

race inspired but very trail capable, extremely light

weight bicycle.

OPTIMAL FOR:

Mountain bikers wanting full

suspension performance at hard tail weight. Custom

design for X/C racer or enthusiast, where the ultimate

fit, comfort and performance must meet full suspension

and a medium-line budget.

SPECS AVAILABLE:

All

geometry parameters can be spec'ed,

subject to manufacturer

production and safety proofing approval. All

geometry parameters can be spec'ed,

subject to manufacturer

production and safety proofing approval.

Custom laser etching

on tubing available.

Designed in Hialeah, made in

Taiwan.

|

|

|

The Executioner

Titanium Cross and gravel grinder

race inspired, extremely light weight bicycle. Great to

race, comfortable on a 100 miles gravel adventure

OPTIMAL FOR:

Cross racer wanting a comfortable

shoulder portage and light weight package. Full custom

design for cross racer or gravel enthusiast, where the

ultimate fit and comfort must meet a medium-line budget.

SPECS AVAILABLE:

All

geometry parameters can be spec'ed, subject to

manufacturer production and safety proofing approval. All

geometry parameters can be spec'ed, subject to

manufacturer production and safety proofing approval.

Custom laser etching

on tubing available.

Designed in Hialeah, made in

Taiwan. |

WHY CUSTOM?

The price of OEM high-end

bikes is skyrocketing because of the race to integrated components

and proprietary aero solutions.

Integrated components reduce fit options, forcing you to adjust

to the bike, instead of the other way around.

Wouldn't it make sense to

have your own high-end bike built to fit you exactly - and

possibly even spend

less?

|

|