|

We saw the full potential of the

Retül and Computrainer technologies and we sought to

make them work together and extract the maximum

performance possible.

We developed our own tools

to complement these two key technologies. We developed a very advanced

system to simulate riding conditions with as much fidelity as

possible. Our own original design and manufacturing of

this rig allows us to

hold the bike and rider in a stable position when

under heavy loads. We affectionately named it the Fit Rig.

The role of the fit rig is very important: Retül measures

the cyclist's body postures to

within 1mm of accuracy. With this level of accuracy, extraneous

data and data noise must be filtered out for the

collected data to be actionable. We must measure the organic movement

of the rider on the bike, not the bike moving around. This

is a requirment that your typical trainer's

front wheel-block can't provide: it slides around too much. The fit rig,

on the other hand, provides a

noise-free data platform with high fidelity to riding

conditions.

Since

Retül motion captures must be done at

high power levels to be significant, the stability of the

fit

rig under high loads is critical. We tested the system up to

1,000 Watts of power output without a hint of a movement. For

out-of-the-saddle data capture for climbing and track

sprinting bike fit protocols, the fit rig is the

only platform you can trust.

Additionally, from an operating

accuracy point of view,

Retül

relies on a perfect

horizon - blindly. It means that the bike has to be perfectly level

axle-to-axle. Retül calculates angles to plumb and a non-leveled

bicycle would return data that's incorrect and

non-actionable - we call it garbage data.

Our rig assures the quality of

data by being perfectly plum by

design and thanks to an

array of calibration tools. It suspends the bike from its axles,

normalizing it to the horizon, no matter what bike type.

Regardless of the wheel

size (650c, 700c, 24", 26", 27.5", 29"), the bike and rider

are always perfectly level.

It accepts all kinds of bicycles:

road, tri, mountain bikes (including Lefty, RS-1, Thru

Axle), cross, track, etc. and a wide range of sizes.

Since we are sought after by many juniors, the fit rig

can accommodate as small as 24in wheels and race

bicycles for kids as young as 7 years old. See here the

junior program.

It's a thing of beauty -

and

quite possibly the only one of its kind in the world.

Our Fit Rig was born on a simple

piece of paper, straight out of the mind of our founder,

owner

and Master bike fitter Steffi.

One of the motivations for its

existence was the very basic necessity for fit to be

successful: a level bike.

This was her thought processes:

"I

see many fitters using the wheel block that came with

their cycle-trainer - I've seen people even use books

under the front wheel! I

don't understand why. The wheel block is not designed

for bike fitting: it's not level; it's not solidly

affixed to the ground. Bike fitting protocols have

the specific need for the bike to be perfectly level

-and stable. When fitters use a wheel block, they are

really setting you up for failure. Customers cannot benefit from the fit done in this fashion. That's

not acceptable. I wasn't going to let this happen to our

customers." "I

see many fitters using the wheel block that came with

their cycle-trainer - I've seen people even use books

under the front wheel! I

don't understand why. The wheel block is not designed

for bike fitting: it's not level; it's not solidly

affixed to the ground. Bike fitting protocols have

the specific need for the bike to be perfectly level

-and stable. When fitters use a wheel block, they are

really setting you up for failure. Customers cannot benefit from the fit done in this fashion. That's

not acceptable. I wasn't going to let this happen to our

customers."

An

additional motivator was the need for a stable platform.

"I realized that with Retül's

1mm measuring accuracy, I needed to create a supporting

apparatus that would help me separate the noise of the

bike's induced secondary motion from the organic

movement of the rider. We have to take motion capture data at high power

level to be meaningful. Everyone pedals pretty when they

are comfy. We learn nothing from that. But with the rider at high power

output we put a lot of

stress on the fit rig. So, I designed the apparatus to

be very stable. This way, the

collected data is accurate and actionable. We can't accept bad

data. The success of the fit depends on it."

And so the bike fitting apparatus,

AKA the Fit Rig, came to life from these very important

observations.

It went through stages of

development and growth. It took input from our talented

fabricator and from our customers. It had to keep up with its

developer's imagination and the growing complexity of

our customer's needs. "This is a

product that's completely transparent to the customer.

It's expected to do its job as intuitively as its

functionality appears to them. But it deserves a lot of

attention, because the fit rig is what allows me to do

what I do best for you."

Much attention was devoted to making

specialty parts to allow for a wide-range of bicycle

sizes and types. "We

studied many bikes and components. We developed the fit

rig with modular and replaceable parts, so it could

transform to accept the many variations in bicycle

design. Ad-hoc parts had to be developed to address the

challenges of ever-changing fork and wheel attachment

points. We work with a wide range of rider, from very

young to very tall. The fit rig had to keep up with all

of that. The latest challenge is with fatty and

plus-sized mountain bikes."

The opportunity for the fit

rig to be also an information and media center

became apparent shortly after the first prototype was

build. In version 2.0 the fit rig was outfitted with a

20in LCD monitor and a laptop PC station. A large boxed

fan was introduced for rider's comfort.

"I wanted my customers to see

the data I see. This way, I can make you part of your

bike fit; get you involved. I can explain each step of

the bike fitting process, helping you understanding what

I am doing and giving you the opportunity for active

feedback. It also helps quantify the improvements from

each change in your position. It's very neat."

In version 3.0, the fit rig

had grown to two side-by-side 22in wide-screen LED

monitors with two laptop PCs, a Computrainer command

center and a tool tray for a full complement of bike

fitting tools at our fingertip. The boxed fan location was further

improved to accommodate the many cooling preferences of

each client. With

tests, re-designs and improvements, the fit rig came to exist as

it does today: the perfect complement to bike

fitting and performance testing.

Come test it for yourself!

A sizing or fit bicycle is a

must-have piece of equipment for any bike fitting

operation that wants to be a legitimate bike fitting

business. It's the foundation for sizing customers

looking to buy a new or used bicycle. It's

the cornerstone of pre-sale consultation services.

If a bike fitter doesn't have a

sizing/fit bicycle (or knows how to use it), then it's not

a reputable business.

"Even though we don't sell

bicycles, much of our activities revolve around

advising customers on the right size and geometry.

Exactly because we don't sell bicycles, our bike sizing

services are sought after for a completely unbiased

advise."

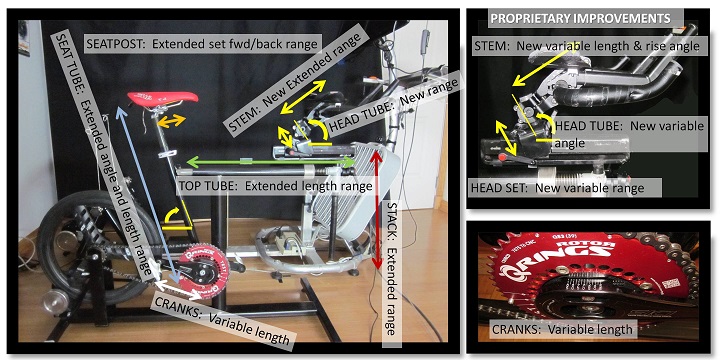

When we were faced with the decision

of purchasing a sizing/fit bicycle, we searched all

commercially available products.

The need for developing our own

custom sizing rig arose from

the realization that there is a gap in these commercially

available sizing/fit bicycles and the advanced features

we felt are needed to properly size modern bicycles.

Our founder, owner and senior fitter Steffi

decided to develop a sizing technology to overcome the

common limitation of all currently available sizing/fit

bicycles: the simulation of the head tube angle and seat

tube angle.

"All commercially available

sizing/fit bicycles are adjustable only in 2D:

horizontally and vertically. They forgo the ability to

emulate angles like the head tube angle and the seat

tube angle because it's more difficult to engineer and

more expensive to fabricate. Some of these sizing/fit

bicycles look very sophisticated. Some are controlled by

servo motors connected to a computer. They look very

fancy. But that doesn't overcome the underlying

limitation. Some attempt to use software to calculate

post-fit the angles. It doesn't work. It's just

inaccurate".

Our fitter knows well. We developed

our own proprietary software, Dream Bike to

attempt overcoming this issue with more sophisticated

algorithms. We introduced a very advanced stem emulation

which accounted for many stem production variations. Our

sizing rig in version 2.x was 2D and relied on our

software to predict head angles. It was good, but not

great. We saw the software predictions get to within

2-3mm of real life. That margin of error is the

difference in one size in a bike (hint: look how the

reach and stack vary by size). This observation was our

motivator in developing our own sizing/fit bike

technology. We discuss this further in our

bike sizing article

and in our custom

geometry page.

The ability to simulate the head tube

angle is vital in determining the right stem length and

rise as well as the correct handlebar reach. The sizing

rig can emulate any head angle and even the headset and

spacers set up for a hi-fidelity bike analog.

During the sizing session, the length

of the stem is used as a check point: if the stem is too

short, it means the geometry being tested is too big;

too long and the bike is too small.

For pre-sales consultation, the head

angle emulation allows us to complete the sizing process

with a spec sheet that includes the correct length and

rise of the stem, so the bike can be spec'ed this way.

For customers looking for advanced aero bikes, this is a

major cost saving feature, as it allows to spec out the

size of the integrated aero bar+stem combination. These

sophisticated aero bars are expensive to replace and

highly proprietary to each brand. Knowing the right size

can make a big difference in cost and waiting time.

The ability to simulate seat tube

angle is crucial in the assessment of the crank length.

These two parameters are locked in a performance dance

that must be closely managed to avoid the potential for

injuries and to maximize performance.

Because we are sought by customers

who travel world-wide to get fitted and can't bring

their own bike, the ability to offer a high-fidelity

bike emulation is vital in their success to take their

fit back home and transfer it successful to their bike

while thousands of mules away from us.

It's a real game changer.

"What this size rig does is simply

amazing. Coupled with the Retül motion capture

technology, it's such an advanced tool, we can use it to

simulate any bike, any size. It's so powerful, we can

design a custom bicycle literally underneath you, sized

for the way you interact with it."

The Size Rig can transform itself and

simulate any bike model geometry and size: Road, Tri,

Mountain. We can input all the relevant bike geometry

specifications of the model(s) you want to test out:

Seat Tube length, Top Tube Length, Head Tube Reach and

Stack,

Quite possibly the most advanced sizing/fit bicycle

because of our unique, proprietary engineering of the

front-end: the only of its kind with variable head

angles.

It is so sophisticated in its

flexibility that it can be used to custom design a bike

to your body specifications.

|